step 1

Before you start to lay your external blocks, identify the highest point on your rising walls. This can be found easily with a laser level. Place your DPC and start your base course at the highest point. Lay the first course on a traditional sand-cement mortar bed. Lay the mortar bed in two rows as shown in the picture. This is the most critical stage of laying the blocks to ensure they are plumb and completely level. This is really important to provide for speed and efficiency during the rest of the construction.

step 2

Mark your door openings on the floor and all of your window openings on your completed base course to remind yourself where you have to stop. It will be convenient for the blocklayer later-on to know where the windows are located

step 3

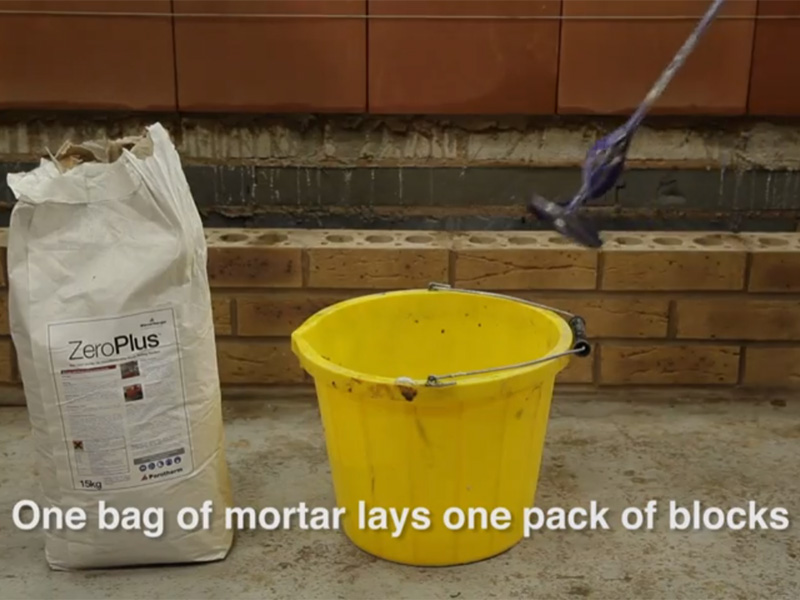

Once your base course is completed, mix a batch of the thin bed mortar provided with the blocks. Mix according to the guidelines on the bag. Quantity-Do not mix more than you need.

step 4

Apply the mortar (mixed close-by) to the Porotherm blocks with a roller applicator.

step 5

Wall ties are easily installed. Use ties approved for use with thin-bed blockwork.

step 6

Repeat the block laying until the precision wall is complete. Up to four times faster than traditional method.

step 7

If additional insulation is specified then it can be applied after the externals walls are erected.

step 8

Porotherm block cutting is really straight forward with the De-Walt Alligator saw. You can also cut with consaw or grinder (stone cutting disc).

step 9

If you are using a wet plaster inside, it will become your airtight layer. If you are going to use a dab and slab finish then you will need an airtight wall. We supply a specific Eco-parge product. This is a breathable product which will fill the smaller gaps in the blockwork. It is an easy and relatively unskilled application process.

step 10

You can use a variety of breathable external insulation systems on the blockwork and finish with the appropriate render choice and colour. Lime based render can be applied straight onto the blocks. Full bed stone as an option can be fixed to the block work with suitable ties or a stone cladding can be used over a base coat of plaster and the appropriate adhesives for fixing the stone panels.