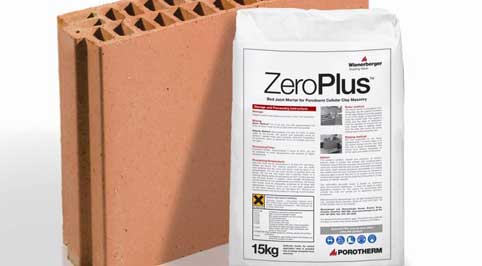

15KG Bag

Porotherm ZeroPlus mortar is a thin-joint mortar for building with Porotherm from zero degrees – so you don’t have to stop in cold weather, saving time and money!

Specifically formulated for Porotherm

The ZeroPlus™ thin-joint mortar is specially formulated for the Porotherm construction system, enabling it to be laid at zero degrees Celsius on a rising scale.

ZeroPlus™ has been validated for use at 0oC by the UK testing house Lucideon. The innovative mixture has been designed to provide the same performance at between 0oC and 3oC as existing thin-joint and traditional mortar, which can only be used at temperatures of 3oC and above.

Reviews

There are no reviews yet.